There are also a few tips that you can use to make a team better design an Ishikawa diagram.

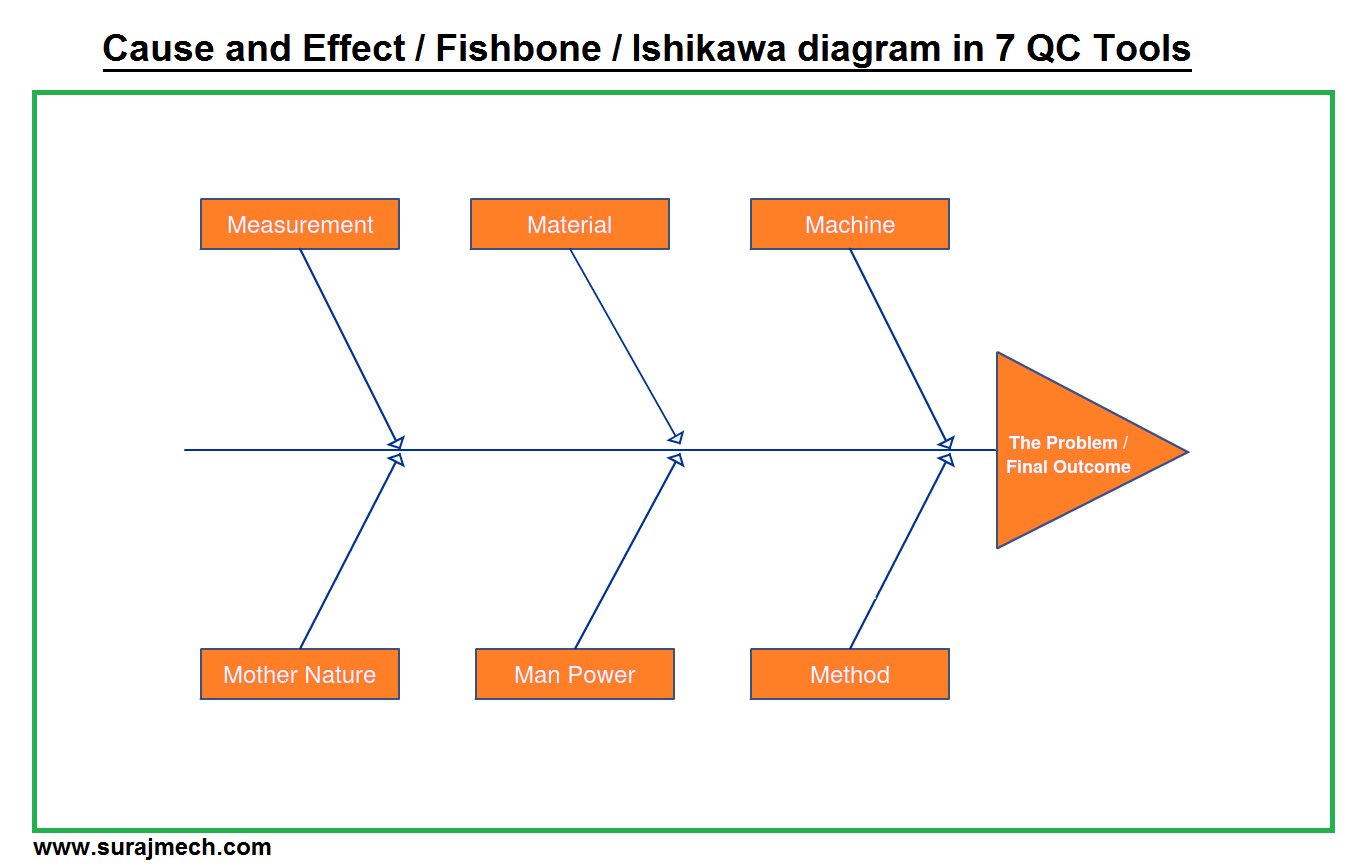

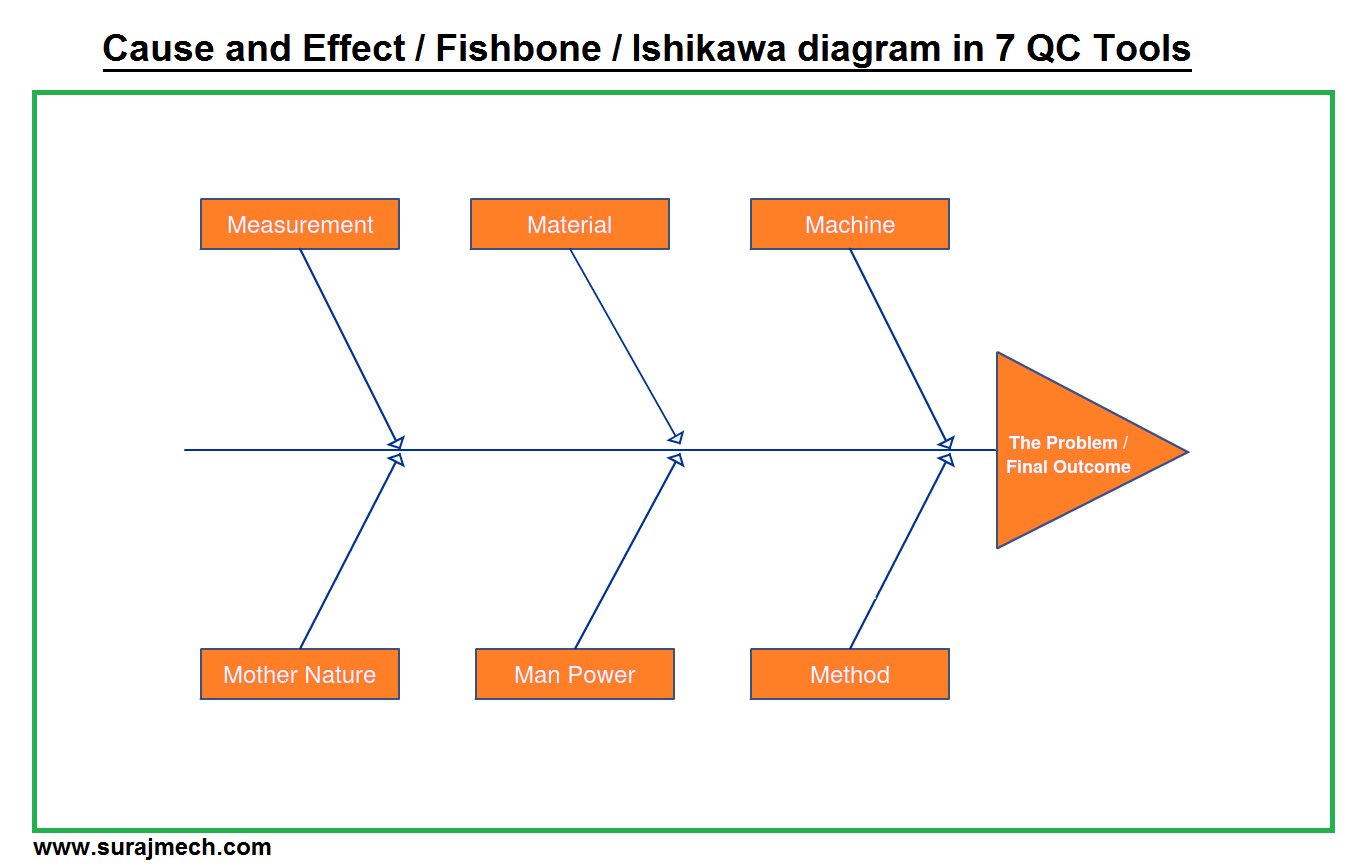

When you’re all out of ideas, look to parts of the chart where ideas are weak. Keep asking ‘Why’ to come up with deeper and deeper causes Put down sub-causes branching from the causes. Ask the question ‘Why does this happen?’ again. Each answer should be a branch from the appropriate category Brainstorm possible causes and ask ‘Why does this happen?’. Put down the causes as branches from the main arrow. If you find this too hard you can use general categories such as: Think of the main categories of causes for the problem or negative effect. Put down the problem in the center of the drawing tool, box it then draw an arrow going to it. There are also a few very easy to do steps: The Ishikawa diagram is very simple to make and you need only basic materials to get it done, materials such as a whiteboard, flip chart and marking pens. It’s also used in quality defect prevention to bring to light factors that cause a negative effect. Other important purposes of the diagram include using it as a methodology for developing product designs that fix practical problems. The diagram’s main purpose is to let management determine which problems or causes have to be tackled in order to promote or avoid a specific event. Respective of its name, the diagram (causal diagram) shows the causes of one event. The Ishikawa diagram is called a fishbone diagram because, you guessed it, it resembles a fish with the body showing the causes and the head the final outcome or final event. The Ishikawa diagram is also popularly termed a fishbone diagram.

It was also first applied in the shipbuilding industry. It was first designed by Kaoru Ishikawa in the 1960s to measure the processes of quality control. It outlines a process and its steps, shows where quality control problems might appear, and determines which resources are needed at given times. The Ishikawa diagram portrays the causes of an effect and is used in manufacturing and other services such as product development. Lean Six Sigma Online Certification & Training.Six Sigma Virtual Instructor-led Training.

CoursesĮxcerpted from The Quality Toolbox, Second Edition, ASQ Quality Press. The authors explore how digitizing one of the seven basic quality tools-the fishbone diagram-using mind mapping can significantly improve the tool. Make one with the Six Sigma package in R.įish(bone) Stories ( Quality Progress) The method behind the fishbone diagram is older than many of its users.

Ishikawa diagram categories software#

Quality Nugget: Creating Ishikawa (Fishbone) Diagrams With R ( Software Quality Professional) A fishbone diagram connects causal links in major categories with an outcome, or effect. The Quality Toolbox, Second Edition Articles Booksīusiness Process Improvement Toolbox, Second Edition You can also search articles, case studies, and publications for fishbone diagram resources. The resulting diagram illustrates the main causes and subcauses leading to an effect (symptom). Start using the fishbone diagram template and analyze process dispersion with this simple, visual tool. "Iron tools" can be considered a "Methods" problem when taking samples or a "Manpower" problem with maintenance personnel. "Calibration" shows up under "Methods" as a factor in the analytical procedure, and also under "Measurement" as a cause of lab error. Note that some ideas appear in two different places. Layers of branches show thorough thinking about the causes of the problem.įor example, under the heading "Machines," the idea "materials of construction" shows four kinds of equipment and then several specific machine numbers. The team used the six generic headings to prompt ideas. This fishbone diagram was drawn by a manufacturing team to try to understand the source of periodic iron contamination.

When the group runs out of ideas, focus attention to places on the chart where ideas are few. Layers of branches indicate causal relationships. Continue to ask "Why?" and generate deeper levels of causes. Write sub-causes branching off the causes. Again ask "Why does this happen?" about each cause. Causes can be written in several places if they relate to several categories. Ask "Why does this happen?" As each idea is given, the facilitator writes it as a branch from the appropriate category. Brainstorm all the possible causes of the problem. Write the categories of causes as branches from the main arrow. If this is difficult use generic headings: Brainstorm the major categories of causes of the problem. Draw a box around it and draw a horizontal arrow running to it. Write it at the center right of the flipchart or whiteboard. Agree on a problem statement (effect). Materials needed: marking pens and flipchart or whiteboard.

0 kommentar(er)

0 kommentar(er)